|

|

|

|

|

Name:

Jet Wash |

|

|

|

Model:

DIC-DM18 |

|

|

|

Supplier:DICHAO (SHANGHAI) INDUSTRY CO.,LTD. |

|

|

|

| Contact Info |

DICHAO (SHANGHAI) INDUSTRY CO.,LTD.

Add: Room 22h,Huadu Building,No.828,Zhangyang Road,

Shanghai,China.

Tel: +86-21-50817278/50817279/50817273

Fax: +86-21-50817161

Contact: Yun Song |

|

|

|

|

Product Introduction: |

|

This equipment is suitable for aircraft engine cleaning operations. Flow figures show flow of 21.5 l / min (to use the flow of 18 ~ 23l/min). The system installed a stainless steel tank, water tank capacity of 300 liters. Heating water temperature of 65 ~ 95oC range adjustable (factory set temperature of 75oC). Heating time of 1 hour (the ambient temperature differs from the different). Power supply 380V, power 12kw (two 6kw heater). Motor drives the pump for the power source. System is equipped with direct spray.

Whole device is equipped with rain in the transport car, the traction in the tractor drag, pulling the maximum speed of 10KM / H.

|

|

1. System structure:

|

|

|

2. Steps

|

|

a) Close the water valve. Required filling with water.

b) Access to power, turn the main power supply, temperature controller set temperature, turn on the heater switch, temperature controller, the device automatically under the control of the set heating requirements.

c) truin off the heating switch and main power

d) Traction to the cleaning position, power, and put on clean lines.

e) Open the pump switch, water valve open, press the gun to start cleaning, after cleaning tank valve off. Ducted nozzle used for cleaning, open the valve to start working.

|

|

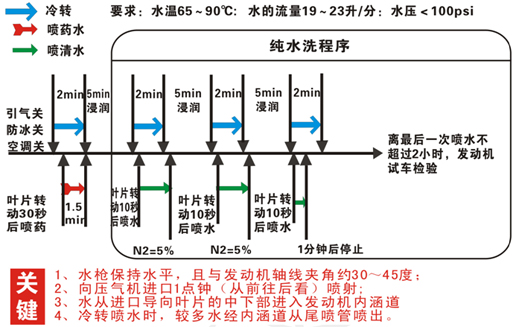

3. Cleaning procedures

|

|

a)The proposed washing procedures

|

|

|

b)清洗时的水流入射方向:水流入射点在一点钟位置水平入射,水流入射角30-45度。如下图所示:

|

|

|

4. Precautions

|

a) For cleaning high temperature (65 ~ 95oC), in operation, use the necessary protective gear, safe use of the device. Prohibited at any time in human mouth spray gun.

b) Regular tank cleaning work, general cleaning once a month.

c) Winter operation is completed, in order to avoid freezing of the liquid, please shine liquid tank。

d) Check all joints on a regular basis, whether leaking.

|

|

5. Routine maintenance

|

a) Always check the connection nuts, screws and a normal state, can tighten loose nuts and screws.

b) Check whether the leaking pipeline phenomenon, timely manner.

c) Maintain the housing body clean, to extend the service life cycle and maintenance of equipment.

|

|

6. Regular testing

|

|

a) Thermometers and flow meters are measuring instruments, please use the units require regular measurement.

|

|

7. Exception handling

|

|

System does not heat

|

|

Check the A, the power is turned on? B, level is too low? C, heating switch on? D, the temperature settings?

|

|

Flow is not enough

|

|

Check the A, the motor is working? B, whether there is leaking? C, hose is bent? Pipe blocked?

|

|

|

Technical Parameter: |

|

For more detail please call us at :+86-21-50817278/50817279/50817273

|

| Related Document: |

|

|

|

|

|